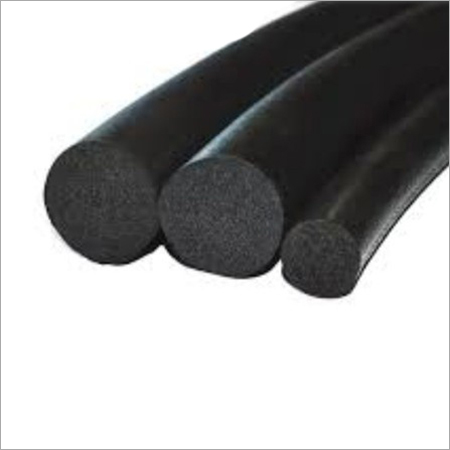

Sponge Rubber Cords

Price 105 INR/ Kilograms

Sponge Rubber Cords Specification

- Tolerance

- 0.5 mm

- Product Type

- Sponge Rubber Cord

- Compression Ratio

- Up to 25%

- Resistance level

- High resistance to weather, ozone, aging, and chemicals

- Surface Finish

- Smooth/Matte

- Size

- Varies as per requirement

- Style

- Round/Solid Extruded

- Hardness

- 15 - 35 Shore A

- Temperature Resistance

- -40C to +120C (can vary by material)

- Feature

- Flexible, compressible, lightweight, weather resistant, insulating

- Components

- Single continuous cord

- Material

- EPDM, Neoprene, Nitrile, NR, Silicone, SBR, or customized rubber

- Diameter

- 2 mm to 50 mm

- Length

- Standard 10 m to 100 m/coil or as per order

- Tensile Strength

- 2 - 8 MPa

- Water Absorption

- Low

- Weight

- Depends on dimension and material

- Natural Rubber

- Available on request

- Flame Resistance Level

- Standard & flame-retardant grades available

- Thermal Conductivity

- Low

- Rubber Type

- Closed cell sponge rubber

- Density

- 0.30 Gram per cubic centimeter(g/cm3)

- Width

- Customizable

- Thickness

- Standard and custom thickness available

- Part Type

- Extruded Rubber Cord

- Color

- Black, White, Red, Grey, Green (available in various colors)

- Ash %

- <5%

- Usage & Applications

- Sealing, cushioning, insulation, vibration control, protection, gasket-making, weatherstripping

Sponge Rubber Cords Trade Information

- Minimum Order Quantity

- 300 Kilograms, ,

- Supply Ability

- 2 Kilograms, , Per Day

- Delivery Time

- 2-3 Days

About Sponge Rubber Cords

We have been able to provide Sponge Rubber Cords. Made using superb quality of rubber, these rubber cords find their use in electrical, power stations, engineering, medical, construction, lighting and shipping and aircraft industries. Our offered rubber cords are known for their high tensile strength, temperature resistance, dimensionally accurate, resistant towards mechanical shocks, high tensile strength and excellent electrical properties. These Sponge Rubber Cords are available in varied diameters and sizes according to the needs of clients. Apart from this, we offer these rubber cords to our clients at market leading prices.

Product Details:

| Color | BLACK , GREW |

| Material | AS REQUIRED |

| Size | AS REQUIRED |

| Brand | G R U |

| Shape | AS REQUIRED |

| Packaging Type | depand ON DEMAND |

| Thickness | AS REQUIRED |

| Hardness | AS REQUIRED |

| Cross Section Type | AS REQUIRED |

| Tolerance | AS REQUIRED |

| Diameter | AS REQUIRED |

Versatile and Customizable Solutions

Our sponge rubber cords can be tailored in size, color, shape, and hardness to precisely meet your projects specifications. Whether you require round, solid cords or specific extruded shapes, we offer bespoke solutions for both small and large-volume needs. Available diameters range from 2 mm to 50 mm, and packaging is supplied coiled in bags or cartons for optimal convenience during transport and handling.

Exceptional Performance in Challenging Environments

Engineered for durability, these cords maintain integrity in extreme temperatures (-40C to +120C), and resist weathering, ozone, aging, and harsh chemicals. Their low water absorption and compressible, insulating nature make them reliable for sealing, vibration damping, and protection tasks, even in demanding automotive, marine, and industrial sectors.

Compliance and Added Features

All products meet RoHS and REACH requirements, ensuring safety and environmental responsibility. Options for adhesive backing, flame-retardant grades, and natural rubber materials are available on request. Expect a smooth or matte finish, low thermal conductivity, and less than 5% ash content, supporting high-quality standards for various industrial applications.

FAQs of Sponge Rubber Cords:

Q: How are sponge rubber cords used in sealing and insulation applications?

A: Sponge rubber cords are commonly employed in sealing, cushioning, insulation, and vibration control tasks. Their flexible, compressible structure allows them to conform to surfaces, effectively blocking air, dust, water, or noise infiltration. The good electrical insulating property makes them suitable for electrical enclosures, while chemical and weather resistance ensures durable performance in outdoor or industrial sealing applications.Q: What customization options are available for sponge rubber cords?

A: Customers can request specific shapes, sizes, colors, hardness levels (15-35 Shore A), and adhesive backing. The diameter can be tailored from 2 mm to 50 mm, and the length per coil ranges from 10 m to 100 m or as required. Both standard and flame-retardant grades, as well as smooth or matte finishes, can be specified to match project needs.Q: When should I choose EPDM or Silicone sponge cords over Nitrile or Neoprene?

A: EPDM and Silicone cords are ideal when excellent UV, ozone, and weather resistance are prioritiessuch as for outdoor, marine, and HVAC applications. Nitrile and Neoprene, on the other hand, provide superior oil resistance and are preferred in environments with oil, grease, or fuel exposure, making them popular for automotive and industrial applications.Q: Where are sponge rubber cords typically applied?

A: These cords are widely used in automotive, HVAC, construction, marine, electrical, and general industrial sectors. They serve as weatherstripping, gasket materials, cable protection, cushioning components, and vibration dampers. Their adaptability to diverse scenarios stems from their broad resistance matrix and customizable properties.Q: What are the benefits of using closed cell sponge rubber cords compared to solid rubber alternatives?

A: Closed cell sponge rubber cords are lighter, more compressible, offer low water absorption, and superior thermal and acoustic insulation compared to solid rubber. This makes them particularly well-suited for cushioning, sealing, and insulation tasks where flexibility and weather resistance are essential while maintaining a low weight profile.Q: How do you ensure the quality and compliance of these cords?

A: All sponge rubber cords adhere to RoHS and REACH standards, ensuring they are safe for use and environmentally friendly. Quality is maintained through careful selection of raw materials, stringent production processes, and thorough testing for physical properties like elongation, tensile strength, and compression ratio.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Cords Category

Natural Sponge Rubber Cord

Price 105 INR / Kilograms

Minimum Order Quantity : 300 Kilograms, ,

Product Type : Sponge Rubber Cord

Feature : Flexible, compressible, lightweight, weather resistant, nontoxic

Color : Black (Other colors available upon request)

Compression Ratio : Typically up to 30% without permanent deformation

EPDM Rubber Cords

Price 105 INR / Unit

Minimum Order Quantity : 300 Kilograms

Product Type : Rubber Cord

Feature : Excellent Weather, Chemical, and Ozone Resistance

Color : Black (other colors available on request)

Compression Ratio : 2035%

EPDM Rubber Cords

Price 105 INR / Kilograms

Minimum Order Quantity : 300 Kilograms, ,

Product Type : Solid Rubber Cord

Feature : Excellent Weather, Ozone & Aging Resistance, UV stable, Nonporous

Color : Black (Standard), can be customized

Compression Ratio : Good Compression Set ( 30%)

Run Sponge Rubber Cords

Price 105 INR / Kilograms

Minimum Order Quantity : 300 Kilograms, ,

Product Type : Sponge Rubber Cord

Feature : Flexible, compressible, lightweight, resilient

Color : Black, White, Red, or as specified

Compression Ratio : Up to 45%

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry